Our Infrastructure

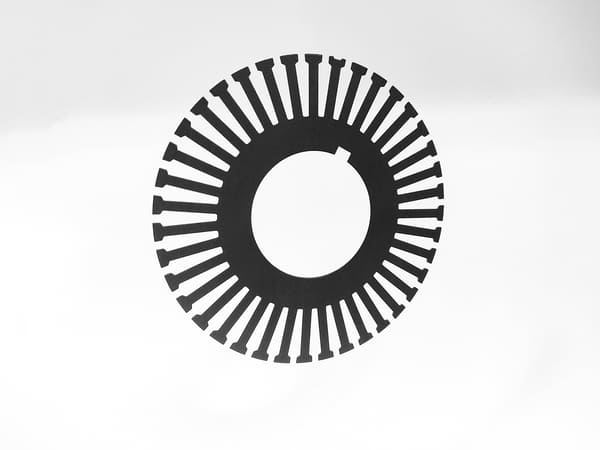

Sheet Metal

High accuracy and adaptability are essential in manufacturing aircraft and aerospace sector parts. The dimensions of the pieces must be exact and long-lasting, independent of the temperature, humidity, or mechanical loads they are subjected to. This is where CACPL sheet metal fabrication comes in to meet the industry's stringent criteria for manufactured products.

CACPL's manufacturing procedures match project needs while offering the quality assurance and efficient delivery that such projects require, thanks to its immense expertise in the aerospace metal fabrication domain. In addition to our in-house inspection and fabrication capabilities, we are working with Aerospace standard vendors for sheet metal capability. Designing, developing, fabricating, laser cutting, CNC bending, shearing, sheet rolling, and deep drawing are all part of our sheet metal portfolio.

Highest level of detail, quality, form, and finish in aerospace sheet metal manufacturing is critical for reliable and safe aircraft. CACPL has perfected the precise, comprehensive process of aircraft sheet metal fabrication to ensure that our customers obtain the best quality parts. CACPL considers every step of the manufacturing process. Throughout the aircraft sheet metal forming process, each part is thoroughly inspected to verify that the highest quality standards are met.

Sheer brilliance and expertise in offering

incredible aerospace solutions.