Our Infrastructure

Testing

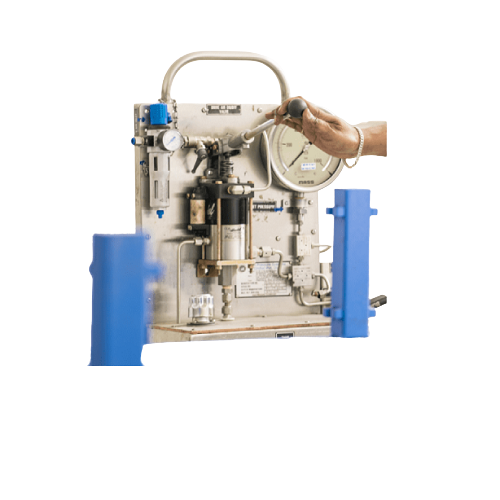

Proof Test Facility

- US-make pressure boosters, which are globally the best facility for oil and gas-proof pressure testing to determine the product integrity, the structural stability & the quality of fabrication and assembly is available with us.

- We ensure to meet the specific requirements of the customers without compromising the safety standards to add to the product reliability.

| Spec | Value |

|---|---|

| Working Medium | "Petroleum based oils, kerosene, diesel, water with 5% soluble oil / De-Ionized Water" |

| Max. Outlet Pressure | Hydraulic Oil (Up to 2500 bar), Deionized Water (upto 1200 bar) |

| Drive Air | <7 bar |

Calibration Facility

- With a master calibrator of precision 0.008% FSO employing gas and oil medium, we have a supremely accurate calibration facility for pressure sensors.

- German Made Masters in Dead Weight calibrators used for Pneumatic and Hydraulic Pressure Calibrators, Differential Pressure Calibrators for Calibrating and Certifying the Pressure Sensors

| Spec | Value |

|---|---|

| Accuracy | 0.01FS |

| Gauge Pressure | 0 to 400 bar |

| Absolute Pressure | 0 to 400 bar |

| Precision | 0.004 % FS |

| Barometric measuring range | 552 ... 1,172 mbar abs |

| Accuracy of Barameter | 0.01 % of reading |

| Programmable | 38 Programs |

Climatic Test Chamber

- CACPL has an excellent German-made Climatic Chamber to ensure and certify product reliability in extreme conditions (temperature, humidity, electrical requirements, thermal requirements) meeting the space and defence requirement.

| Spec | Value |

|---|---|

| Testing area of chamber | 750 x 580 x 765mm (H x W x D) |

| Testing Temperature range | -72°C to +180°C |

| Humidity | 0 to 99% RH |

Universal Testing Machine

- CACPL employs this top-of-the-line UTM for spring calibration to ensure that valve or module actuations produce the intended outcomes like tension, compression, etc. by exerting tensile, compressive or transverse stresses

| Spec | Value |

|---|---|

| Weight with Typical load cell | "141 Kg (312 lb.)" |

| Load capacity | 50kN (5000 Kgf, 11250 lbf) |

| Maximum Power Req. | 700VA |

| Maximum Speed | 500 mm/min (20 in/min) |

| Minimum Speed | 0.005 mm/min(0.0002 in/min) |

| Total vertical test space mm | 1193, (47 inch) |

Vibration Shaker

- Top Class German-made air-cooled vibration shakers to stimulate vibrational environment on subassemblies and assemblies. The Parts and Products conformity are subjected to Active pressure or Passive pressure for testing to assure the Quality & Acceptance conformances of customer and ASD standards requirements

| Spec | Value |

|---|---|

| Slip table dim. | 610 x 610 mm |

| Mass of moving element | 31.6 kg |

| Armature resonance (fn) | 2650 Hz |

| Useful frequency range | D.C. to 3000 Hz) |

| Sine force peak | 35585N |

| Random force rms (ISO5344) | 35585N |

| Half sine peak bump force | 106752N |

Data Acquisition Facility

- CACPL includes an efficient and dedicated data acquisition testing lab especially for voltage, current & and temperature measurement.

| Spec | Value |

|---|---|

| Software | NI Platform |

Thermo Vacuum Facility

- A unique environmental testing chamber facility (Thermo vacuum chamber) with cutting-edge technology that creates vacuum as in space environment with applying extensive range of temperature.

| Spec | Value |

|---|---|

| Chamber Size | 700 x 700 x 700 mm |

| Operating Temperature range | -70°C to +150°C |

| Operating Vacuum level | Better than 1x10-5 |

Pressure Flow Test Facility

- CACPL has a robust pressure flow test facility that complies with all safety regulations concerning surrounding, operating and monitoring system The chamber is encompassed with Nitrogen & Helium test setup and a dedicated high pressure compressor.

| Spec | Value |

|---|---|

| Max Pressure | 400 bar |

Motor Characteristics Facility

- CACPL has included a US-made motor testing system to monitor and analyse the speed-torque characteristics, armature resistance and peak torque of motors.

| Spec | Value |

|---|---|

| Max Torque Range | 6.2 N-m |

| Drag Torque De-Energized at 100 rpm | 23 N-m |

| Nominal Input Inertia | 1.49 x 10-3 |

| Max Power Ratings | 1400 Watts (5 mins) |

| Max Speed | 35000 RPM |

| Break Cooling Method | Blower |

Mass Spectro Helium Leak Detector

- CACPL uses the Mass Spectro Helium Leak Detector to discover leaks in brazing and welding manufactured space application items.

| Spec | Value |

|---|---|

| Measuring Range | 5x10 -12 -1 mbar l/s |

| Sensitivity | 1x10-12 mbar l/s |

| Max. Operating Pressure | 25 mbar |

| Smallest detectable He leak rate (Vacuum mode) | 5x10-12 mbar l/s |

| Smallest detectable He leak rate (Sniffer mode) | 5x10-8 mbar l/s |

Cryo Test Facility

- With the use of the LN2 medium, CACPL utilises a state-of-the-art facility to assess a product's withstanding potential, particularly in low-temperature settings.

| Spec | Value |

|---|---|

| Temperature range | Ambient to -170°C |

| Cooling medium | LN2 |

| Rate of Heating and cooling | 0.1 to 3°C /min |

Salt Spray Chamber

- Specialised Cyclic Corrosion Test Chambers for the surface treatment plant.

| Spec | Value |

|---|---|

| Working room temperature | RT?5°C~50°C (The setting value cannot be lower than the current ambient temperature) |

| Saturated Tower temperature | (plus)40°C~+45°C |

| Rate of Heating and cooling | 0.1 to 3°C /min |

Humidity Chamber

- CACPL performs condensing humidity testing in the surface treatment plant utilising specialised humidity cabinets.

| Spec | Value |

|---|---|

| Temperature range & Accuracy | 10°C to 50°C, ± 1°C |

| Humidity range & Accuracy | 40% to 95%, ± 3% |

Hydrogen Embrittlement Facility

- We perform mechanical hydrogen embrittlement testing according to ASTM F519.

Coating Thickness Gauge

- We offer coating thickness measurement using Eddy current gauges.

Particle Counter (Liquid)

| Spec | Value |

|---|---|

| Working Medium | DM Water, Acetone, IPA |

| Measurement Std | NAS 1638 or ISO 4402/440 |

| Measurement range | Class 0-N2 |

| Particles Size | 1-50 microns |

| Principle | Light Blockage |

Air Borne Particle Counter

- Most versatile TSI Particle Counters are used.

| Spec | Value |

|---|---|

| Range | From 0.3 microns to 5 microns |

| Display | Colour LCD Display |

| Storage capacity | 3,000 Sample points |

| Type | Portable Laser diode type |

| Sampling rate | 1 CFM |

Sheer brilliance and expertise in offering

incredible aerospace solutions.

SEND ENQUIRY